Recognizing UH 60 Parts: An Overview for Airplane Technicians

Recognizing UH 60 Parts: An Overview for Airplane Technicians

Blog Article

The Value of Correctly Sourcing UH-60 Components for Safe and Efficient Workflow

The significance of properly sourcing UH-60 components can not be overemphasized, as the integrity and security of air travel procedures hinge on the quality of these components. Using certified components not only makes sure conformity with rigorous engineering standards however also minimizes the risks connected with ineffective options.

Understanding UH-60 Component Specs

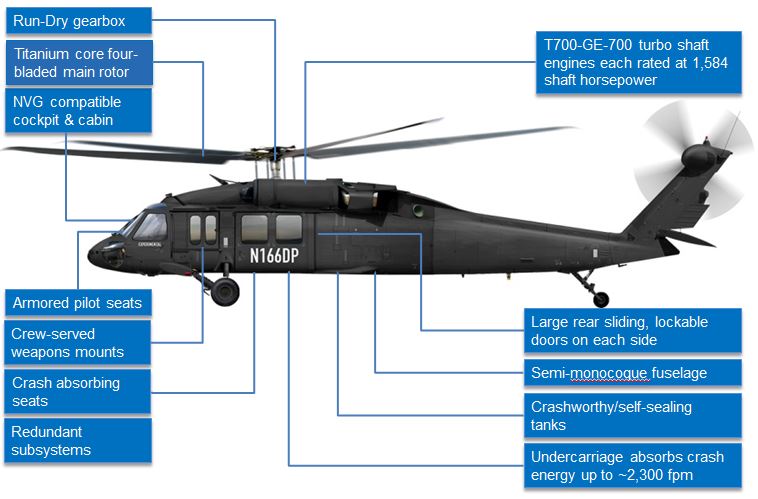

Recognizing the intricacies of UH-60 component specifications is essential for ensuring operational effectiveness and safety in air travel upkeep. The UH-60, widely made use of in civilian and military applications, requires elements that fulfill stringent engineering and governing standards. Each component is thoroughly designed to execute under details problems, and deviations in specifications can bring about performance failings or safety and security risks.

Component specs include different attributes, consisting of material structure, dimensional resistances, and functional limits. As an example, rotor blades have to stick to precise weight and wind resistant accounts to assure ideal trip characteristics. In addition, parts need to undertake strenuous testing to confirm their dependability and sturdiness within the demanding settings typical of aeronautics operations.

In addition, understanding the qualification processes connected with UH-60 elements is crucial. Each part may birth markings showing compliance with army or market criteria, making certain that it has actually undergone the required examinations and high quality assessments. This compliance not just safeguards the airplane's performance but also cultivates liability amongst producers and providers. Consequently, thorough understanding of part specifications is vital for maintenance workers, enabling them to determine authentic components and preserve the operational honesty of the UH-60 fleet.

Risks of Using Substandard Components

The honesty of aviation procedures depends upon the quality of components utilized in aircraft upkeep, particularly for the UH-60. Utilizing subpar parts positions significant risks that can endanger both safety and security and operational efficiency. These parts might not meet the strenuous standards developed for armed forces aviation, causing uncertain efficiency and prospective system failings.

Substandard components can result in enhanced wear and tear on critical systems, inevitably shortening the life expectancy of the aircraft and demanding costly repairs or replacements. Additionally, the use of inferior products may cause catastrophic failures during trip, threatening the lives of team participants and travelers alike.

In addition, dependence on non-compliant parts can subject drivers to regulative and legal consequences, as aircraft has to abide by rigid guidelines set forth by governing bodies. This can result in grounding of the airplane and considerable functional delays.

Advantages of Certified Elements

Qualified components offer a wide variety of benefits that substantially improve the security and reliability of UH-60 operations - uh 60 parts. One of the primary benefits of these components is their adherence to stringent high quality standards. Qualification processes guarantee that each component has actually undertaken rigorous screening and evaluation, thereby verifying its efficiency and durability under numerous operational conditions

Professionals can be positive in the reliability of these components, decreasing the possibility of unintended fixings and boosting general functional efficiency. Ultimately, investing in certified parts is important for the secure and effective operation of UH-60 airplane.

Sourcing From Reliable Vendors

When sourcing parts for UH-60 airplane, partnering with trusted suppliers is important to ensuring top quality and integrity. The security and performance of armed forces aircraft depend substantially on the integrity of their parts, making it necessary to select providers with a proven track document in the sector. Respectable providers stick to rigorous high quality control measures and commonly hold appropriate accreditations, which act as a testament to their commitment to excellence.

Along with high quality assurance, established vendors provide extensive support solutions, consisting of technological aid, service warranty programs, and prompt distribution. This level of engagement is necessary for preserving operational readiness and reducing downtime. In addition, credible suppliers are usually more clear regarding their sourcing techniques, guaranteeing that the components offered fulfill strict regulatory criteria and are suitable with existing systems.

It is additionally advantageous to take into consideration suppliers that concentrate on UH-60 components, as pop over to this site they possess thorough expertise of the airplane's requirements and needs. By leveraging the know-how of these vendors, operators can boost the safety and effectiveness of their operations, eventually bring about boosted objective success. As a result, investing time in sourcing from trusted vendors is an essential step towards attaining ideal efficiency in UH-60 aircraft procedures.

Long-Term Price Efficiency

Achieving long-lasting cost effectiveness in sourcing UH-60 parts requires a tactical method that stabilizes initial investment with ongoing operational costs. More hints Organizations must prioritize high quality over cost, as substandard components might cause frequent repair services and boosted downtime, inevitably pumping up general expenses. By purchasing trusted, licensed parts, operators can enhance the airplane's performance and durability, reducing the threat of unexpected failings.

In addition, developing lasting relationships with reliable providers can yield monetary advantages, such as bulk getting price cuts and beneficial repayment terms. These partnerships promote access to exceptional products and technological support, guaranteeing that the sourcing process lines up with operational requirements and regulative standards.

In addition, implementing a systematic stock monitoring method enables better forecasting of component needs, decreasing excess supply and connected holding costs. Frequently reviewing provider performance and part integrity can likewise educate future purchasing choices, allowing organizations to adapt to advancing functional needs effectively.

Eventually, a concentrate on long-lasting price performance in sourcing UH-60 components not just safeguards operational integrity but likewise contributes to a much more lasting monetary model, enabling reinvestment in crucial aviation capacities.

Final Thought

In conclusion, the proper sourcing of UH-60 parts is vital for keeping risk-free and reliable aviation operations. Sticking to stringent specs and utilizing certified elements reduces the dangers linked with substandard components.

The relevance of effectively sourcing UH-60 parts can not be overemphasized, useful source as the stability and safety of aeronautics procedures pivot on the high quality of these parts.Comprehending the ins and outs of UH-60 component specifications is essential for ensuring functional effectiveness and safety and security in aeronautics maintenance. Extensive expertise of component specs is indispensable for maintenance employees, enabling them to determine genuine elements and keep the functional stability of the UH-60 fleet.

When sourcing parts for UH-60 airplane, partnering with credible providers is essential to ensuring quality and dependability.Achieving long-term price efficiency in sourcing UH-60 components needs a critical method that balances preliminary financial investment with continuous functional costs.

Report this page